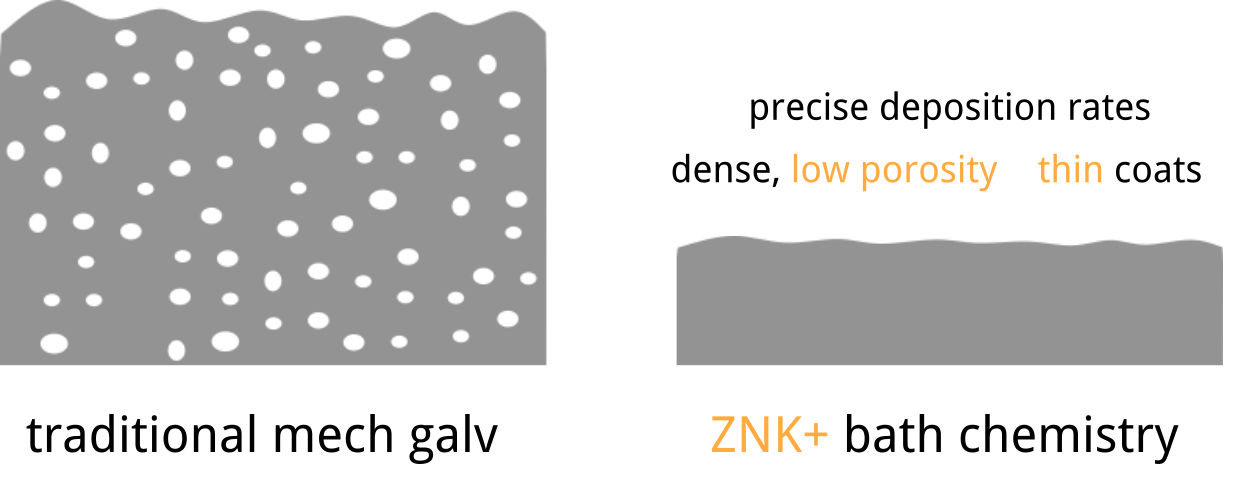

Another key element of the plating protocol is proprietary bath chemistry to promote complete and stable deposition of the metal powders onto the steel substrate. The goal is to maximize the uptake of the metal powders, and promote a relatively thin, dense base layer with very low porosity.

Our optimized plating chemistry is specifically designed to produce thin, low-porosity coating layers on metal surfaces. This is achieved through a combination of advanced formulation techniques and precise control of the plating process.

The first step in producing a thin, low-porosity coating is to carefully select the appropriate plating chemicals and additives. Our team of chemists uses advanced formulation techniques to develop a plating solution that is optimized for producing thin, dense coatings. This solution is carefully balanced to provide the right balance of adhesion, coverage, and corrosion resistance, while minimizing the formation of pores and other defects in the coating.

Once the plating solution has been developed, the next step is to carefully control the plating process to ensure that the coating is applied evenly and consistently. This involves carefully controlling the temperature, pH, and concentration of the plating solution, as well as the current density and other process parameters. By carefully controlling these factors, we can minimize the formation of pores and other defects in the coating, resulting in a smooth, dense, and uniform coating layer.

Overall, our optimized plating chemistry and precise process control allow us to produce thin, low-porosity coating layers that provide superior performance and long-term value for our customers.