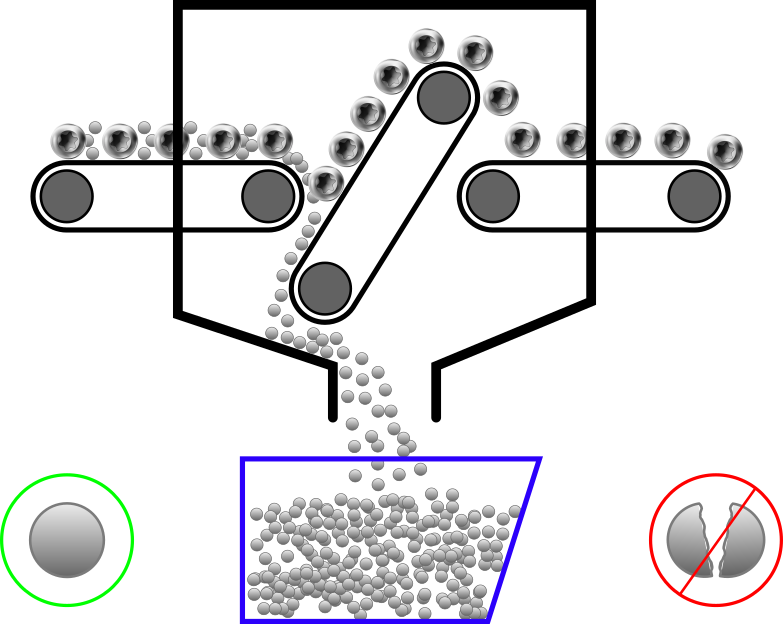

One drawback of traditional mechanical plating, especially when plating small or recessed parts, is bead breakage. Broken beads can become lodged in recesses and other concave features, rendering parts unusable. At ZNK+, glass beads are separated and screened from the metal fasteners during the mechanical plating process using a combination of mechanical and magnetic methods, utilizing a novel design to recover re-use beads intact, preventing recess fills.

After the plating process is complete, the fasteners are typically placed into a specialized separator machine. This machine uses a combination of vibration, air flow, and other mechanical means to separate the beads from the fasteners. The beads are typically lighter and smaller than the fasteners, and are easily separated from the metal parts.

Once the beads have been separated from the fasteners, they are typically screened to remove any debris or impurities. This is typically done using a series of screens or filters, which are designed to capture the beads and allow the debris to pass through. The screened beads are then collected and can be used again in the plating process, while the debris is discarded.

In some cases, magnetic separation may also be used to help remove the beads from the fasteners. This involves passing the fasteners and beads through a magnetic field, which attracts the beads and allows them to be easily removed from the fasteners.

Overall, the separation and screening of the glass beads from the metal fasteners is an important step in the mechanical plating process. It ensures that the beads are properly separated from the fasteners and are free from impurities, allowing them to be reused and ensuring the quality and performance of the plated parts.