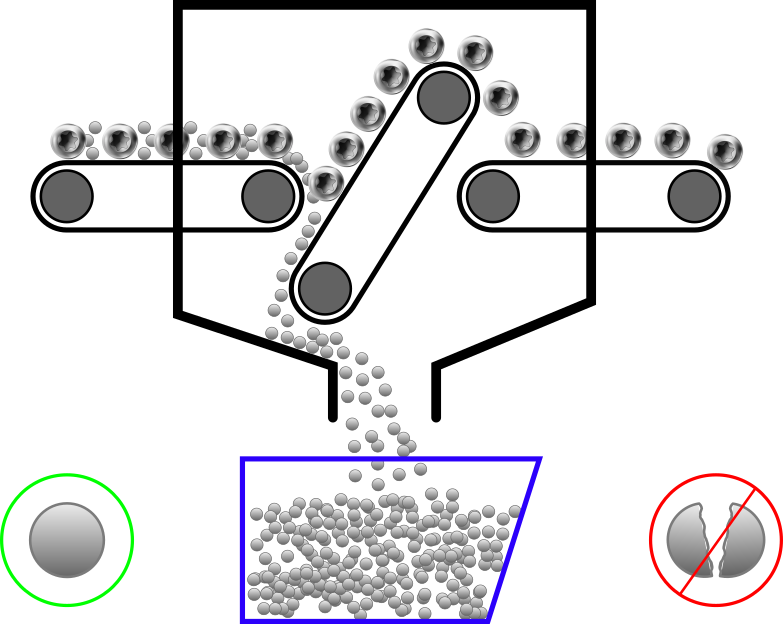

Powder Mix

The multi-metal powder mix is one of the foundations of producing a durable, highly protective base layer than can, on its own, withstand highly corrosive outdoor environments.

Our proprietary zinc tin multiple metal powder mix is a unique blend of zinc, tin, and other metal powders that are combined to create a durable coating over steel fasteners. This coating material provides a number of benefits over traditional galvanizing methods, including improved corrosion resistance, enhanced mechanical properties, and a longer service life.

Read More